The global automotive marketplace has created unprecedented opportunities for vehicle owners seeking replacement or upgraded engines. Import engines, particularly from Japanese domestic markets, offer compelling alternatives to domestic replacements, often featuring lower mileage, meticulous maintenance histories, and proven reliability. However, navigating this market requires understanding quality standards, regulatory compliance, and proper selection criteria to ensure successful installations and long-term satisfaction.

The Appeal of Japanese Domestic Market Components

Japanese automotive culture emphasizes regular maintenance and relatively short vehicle ownership cycles. Strict vehicle inspection requirements and cultural attitudes toward vehicle age result in many low-mileage vehicles being retired from service. This creates a robust market for used components, particularly engines and transmissions, that retain substantial service life. Japanese domestic market engines often feature specifications and technologies unavailable in export versions, sometimes offering superior performance characteristics.

The quality control standards in Japanese manufacturing have earned worldwide recognition. This attention to detail extends throughout the production process and vehicle lifecycle, resulting in components that frequently exceed international counterparts in reliability and durability. Combined with lower average annual mileage in Japan compared to countries like the United States, these factors make Japanese-sourced engines attractive options for replacement applications.

Understanding Mileage and Condition

When evaluating import engines, mileage provides important but not exclusive insight into condition. Japanese vehicles typically accumulate fewer annual miles than their American counterparts, meaning a five-year-old Japanese engine might show significantly less wear than a similarly-aged domestic unit. However, mileage alone doesn’t tell the complete story—maintenance history, operating conditions, and storage practices all influence engine condition.

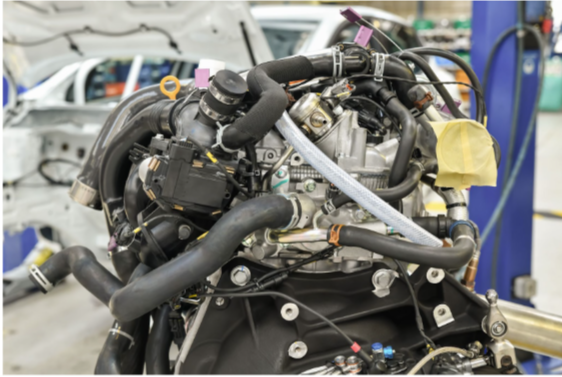

Reputable suppliers provide detailed information about engine origins, including removal dates, prior vehicle applications, and visual condition assessments. Look for suppliers who offer compression testing results, leak-down test data, and photographic documentation of engine condition. These details help identify potential issues before purchase and installation.

Compression and Leak-Down Testing

Compression testing measures the pressure each cylinder generates during the compression stroke, indicating piston ring seal, valve seating, and overall mechanical condition. Consistent compression readings across all cylinders suggest good mechanical health, while significant variations may indicate wear or damage requiring attention. Professional mechanics use compression testing as a fundamental diagnostic tool when assessing engine condition.

Leak-down testing provides additional insight by pressurizing cylinders and measuring air escape rates. This test identifies specific leak sources—past piston rings, through valves, or via head gaskets—offering more detailed condition assessment than compression testing alone. Engines demonstrating good compression and minimal leak-down typically provide reliable service after installation.

Regulatory Considerations and Compliance

Import engine installations must comply with emissions regulations and vehicle safety standards. In the United States, the Clean Air Act requires vehicles to maintain emissions equipment appropriate to their model year. Installing an engine lacking required emissions controls or from a significantly different model year can create compliance issues, potentially resulting in failed inspections or legal complications.

Most jurisdictions allow same-generation engine swaps maintaining equivalent or superior emissions controls. However, regulations vary by state and locality, making research essential before purchasing import engines. Some states require specific certifications or documentation proving emissions compliance, while others maintain more lenient standards. Consulting local regulatory authorities and experienced installation shops prevents costly mistakes and ensures legal compliance.

Finding Reputable Suppliers

The import engine market includes both reputable businesses and questionable operators. Distinguishing between them requires careful evaluation of business practices, customer reviews, and quality guarantees. Established suppliers typically offer warranties, detailed engine documentation, and responsive customer service. They maintain organized inventories, proper storage facilities, and established shipping procedures ensuring engines arrive in good condition.

Customer reviews and references provide valuable insights into supplier reliability and product quality. Look for patterns in feedback—consistent positive reviews regarding product quality, shipping practices, and problem resolution indicate reliable suppliers. Conversely, recurring complaints about misrepresented conditions, shipping damage, or poor customer service suggest businesses to avoid.

When seeking quality replacement powerplants, particularly for popular Japanese brands, exploring options like imported JDM Mitsubishi engines from established suppliers ensures access to thoroughly inspected, properly documented components backed by reasonable warranties.

Warranty and Return Policies

Understanding warranty terms protects against receiving defective or misrepresented products. Reputable suppliers offer warranties covering major internal components, typically ranging from thirty days to six months. Read warranty terms carefully, noting coverage exclusions, claim procedures, and customer responsibilities. Some warranties require professional installation documentation, while others mandate specific break-in procedures.

Return policies provide additional protection if engines arrive damaged or significantly different from descriptions. Clarify return procedures, restocking fees, and shipping responsibility before purchasing. Document engine condition immediately upon arrival, photographing any damage or discrepancies. Prompt communication with suppliers regarding issues facilitates resolution and protects your investment.

Installation Considerations

Professional installation maximizes success probability when installing import engines. Experienced mechanics familiar with specific makes and models navigate potential compatibility issues, adapt mounting points, connect electronics properly, and ensure all systems function correctly. While DIY installation appeals to mechanically-inclined enthusiasts, professional installation provides peace of mind and often maintains warranty coverage.

Necessary supporting components—engine mounts, wiring harnesses, exhaust adapters, and cooling system components—must be addressed during installation planning. Some engines require additional parts for proper integration with existing vehicle systems. Budget for these ancillary components alongside the engine purchase price to avoid unexpected expenses during installation.

Break-In Procedures

New and rebuilt engines require careful break-in procedures, and even used import engines benefit from conservative initial operation. Break-in allows piston rings to properly seat, bearings to develop proper oil films, and components to mate correctly. Typical break-in procedures involve avoiding full-throttle acceleration, varying engine speeds, and performing early oil changes to remove initial wear particles.

Follow manufacturer or supplier recommendations regarding break-in procedures and initial service intervals. Conservative early operation establishes good habits while protecting your investment. Most engines complete break-in within several hundred miles, after which normal operation resumes.

Maintenance After Installation

Newly-installed engines deserve meticulous maintenance during initial service life. Perform oil changes at shorter intervals initially, removing wear particles and combustion byproducts. Monitor fluid levels, watch for leaks, and listen for unusual noises indicating potential issues. Early detection and correction of problems prevents minor issues from becoming major failures.

Maintain detailed records of installation work, initial services, and ongoing maintenance. Documentation proves valuable for warranty claims, future service work, and eventual resale. Good records demonstrate conscientious ownership and enhance vehicle value.

Conclusion

Import engines offer compelling alternatives to domestic replacements, particularly for Japanese vehicle owners seeking quality, reliability, and value. Success requires understanding quality indicators, navigating regulatory requirements, selecting reputable suppliers, and ensuring proper installation and maintenance. With careful research and attention to detail, import engines provide cost-effective solutions delivering years of reliable service while maintaining vehicle performance and value.